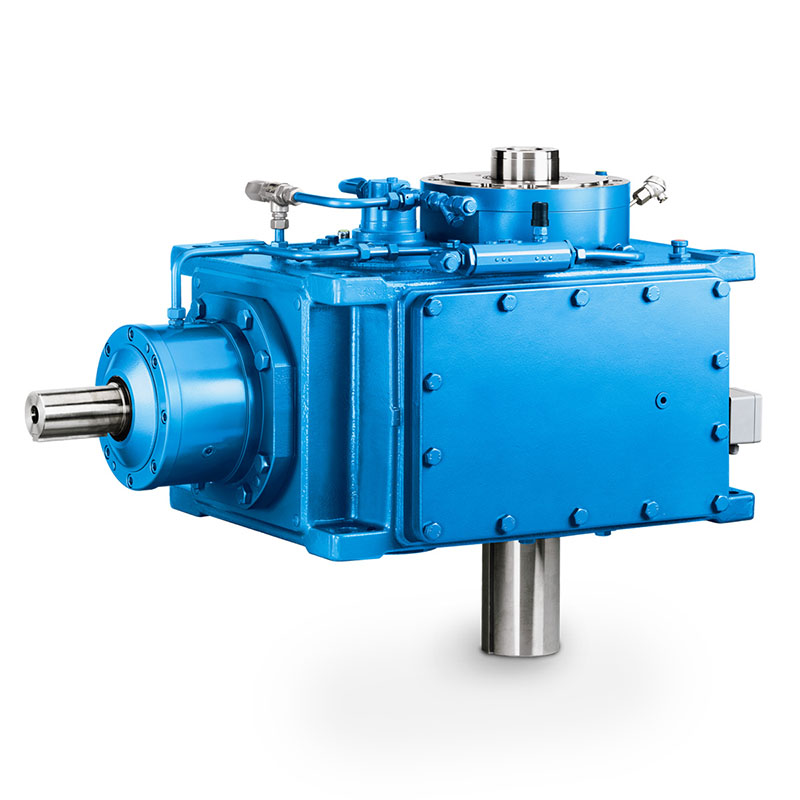

Water turbines are fluid flow engines converting potential and kinetic energy contained in water into mechanical energy which then in a generator is converted into electrical energy. Gear units are needed to gear up the low turbine speed into high generator speed (speed increasing ratio), to transmit the turbine torque and pass it on the generator.

Design

Water turbines are fluid flow engines converting potential and kinetic energy contained in water into mechanical energy which then in a generator is converted into electrical energy. Gear units are needed to gear up the low turbine speed into high generator speed (speed increasing ratio), to transmit the turbine torque and pass it on the generator.

FLENDER gear units for water turbines are a completely new design. Outstanding innovations are:

- more sizes with a reduced variety of parts,

- higher operational reliability combined with increased power capacity,

- input shaft d2 led through vertically downward is provided with a so-called oil retaining tube which ensures that the shaft exit is kept absolutely oil-free.

- particularly strong input and output shaft bearing arrangements - with additional thrust bearing - absorb high external axial and radial forces from the turbine. It is possible to insert special bearing arrangements in case of high runaway speeds (on request).

- in case of need, input shaft d2 can be provided with a hollow bore for the connection of the turbine adjusting linkage (on request).

- the input side flange coupling and possibly also the flexible coupling between turbine wheel and gear unit input shaft d2 are part of our standard product range.

- important add-on pieces like the bell housing between gear unit and generator including the flexible coupling or the integrated disk brake (blocking brake) as well as monitoring equipment (e.g. bearing and temperature monitors, etc.) and possibly oil/air coolers are supplied by us (on request).

Mounting position

FLENDER gear unit types H2WV and B2WV for water turbines are available for vertical mounting position. The LS gear unit input shaft d2 coupled with the turbine is arranged vertically downward. In case of gear unit type H2WV the generator in flange-mounted design (assembly option IMV1) is normally arranged above a bell housing above the gear unit.

In case of gear unit type B2WV the generator in foot-mounted design (assembly option IMB3) may be arranged beside the gear unit. Other mounting positions, e.g. inclined position, on request.

Noise behaviour of the gears

New concepts were applied to clearly improve the noise emission of the gears by

- grinding the bevel gears,

- designing noise-absorbing housings by means of the MASAK-computing program, and

- achieving exceptionally large contact ratios.

Thermal conduction

FLENDER gear units for water turbines not only have a high efficiency but also a favourable thermal conduction

- through enlarged housing surface areas,

- because large fans incorporating a new type of air conduction fan cowl are being used.

The selection of FLENDER gear units is based on a lower maximum oil temperature. By that, the operational reliability will be increased and the cost of maintenance reduced due to longer oil change intervals.

Storing

FLENDER gear units have been designed according to a new unit construction principle. Through this, the variety of parts could be reduced. The parts are mainly on stock enabling the FLENDER manufacturing plants worldwide to deliver at short term.