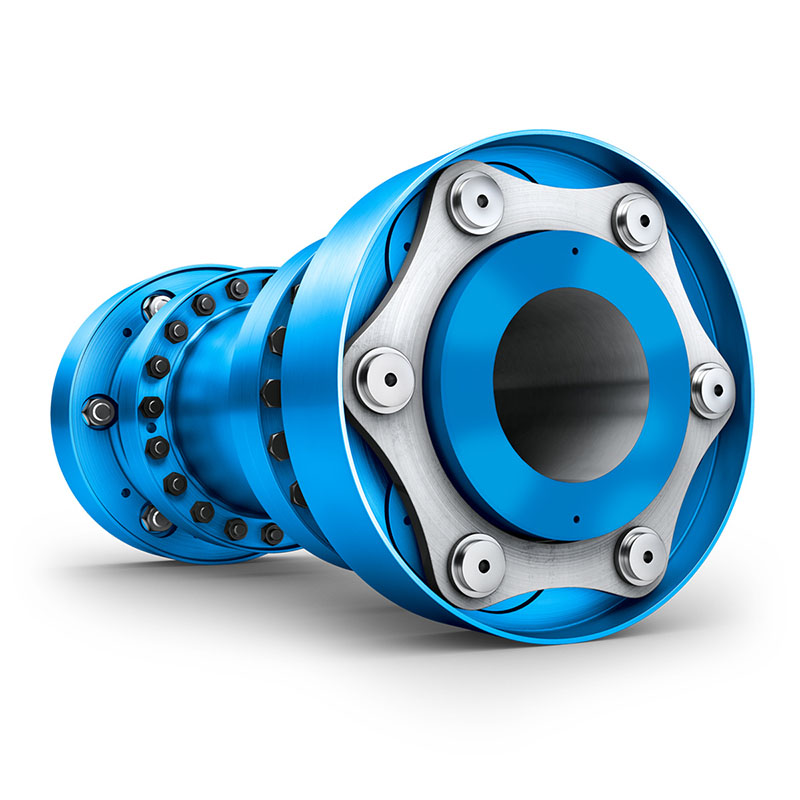

TOP SPEED: 720 KM/H

- Torsionally rigid, backlash-free, all-steel multiple-disk coupling for high-speed applications

- Nominal torque range from TKN = 1,000 Nm up to 588,500 Nm with 16 sizes

- Temperature range: from -40 °C to +280 °C

ARPEX ART high performance couplings consist of pure expertise combined with the greatest possible power density. They are used in all high-speed drive systems that require torque transfer where shaft misalignment is occurring simultaneously. The ARPEX ART leaves nothing to be desired in terms of both bore capacity and safety: their compact design allows them to compensate for all of the expected misalignments in a very small space and, at the same time, gives them the highest possible torque capacity, the lowest possible weight and a very good center of gravity.

The double-cardan principle used in the ARPEX ART enables very high radial offsets, even under great loads. With thin, individual disks, the reaction forces that occur with shaft misalignments remain relatively low. The disks of the ARPEX ART high-performance coupling consist of high-alloyed stainless spring steel, and all of the other coupling components are made of high-quality, heat-treated steel.

One strength of the ARPEX ART is the achievable balance quality. This is the result of very high processing quality, extremely low production tolerances and high-precision assembly processes.

Your benefits at a glance

- Lubrication of disks not required

- Torque transfer with no play due to patented, positive compression screw fitting of the disk pack

- High balance quality

- Meets the requirements of API 671

- Suitable for use in potentially explosive environments; certified according to 2014/34/EU (ATEX)

- Easy assembly with factory-mounted half-couplings and/or transfer units

- Low reaction forces

- Installation and removal of the couplings without axial misalignment

Made in Germany, worldwide in use

- Marine and Shipbuilding: single-engine ships, multi-engine ships, dredgers, generator gearboxes, installation vessels

- Oil and Gas: pumps, fans, compressors, air condensers

- Power Generation: generators, gas turbines, boiler feed pumps

- Chemicals and Pharmaceuticals: pumps and compressors

- Sugar: generators, steam turbines

- Other fields of application: test benches

Did you know?

In addition to our tried-and-tested MHM and BVB series, we offer others including the balance optimized series XVX. The arrangement of the coupling's parts enables the lowest torque load on the connecting shafts. This series is outstanding for use in high-speed turbine drives with exacting requirements concerning the gravity position and the weight of the half coupling.