CALMING EFFECT: OPERATIONAL RELIABILITY EVEN IN CASE OF THE HIGHEST VENTILATION FORCES

Wet Cooling Towers are those buildings where the water that was heated by industrial or power generation processes is cooled, again. The heat is given off to the environment. The water to be cooled is sprayed and distributed over the splash fills. As a result, the water temperature drops when the evaporation heat is withdrawn and the air gets humified.

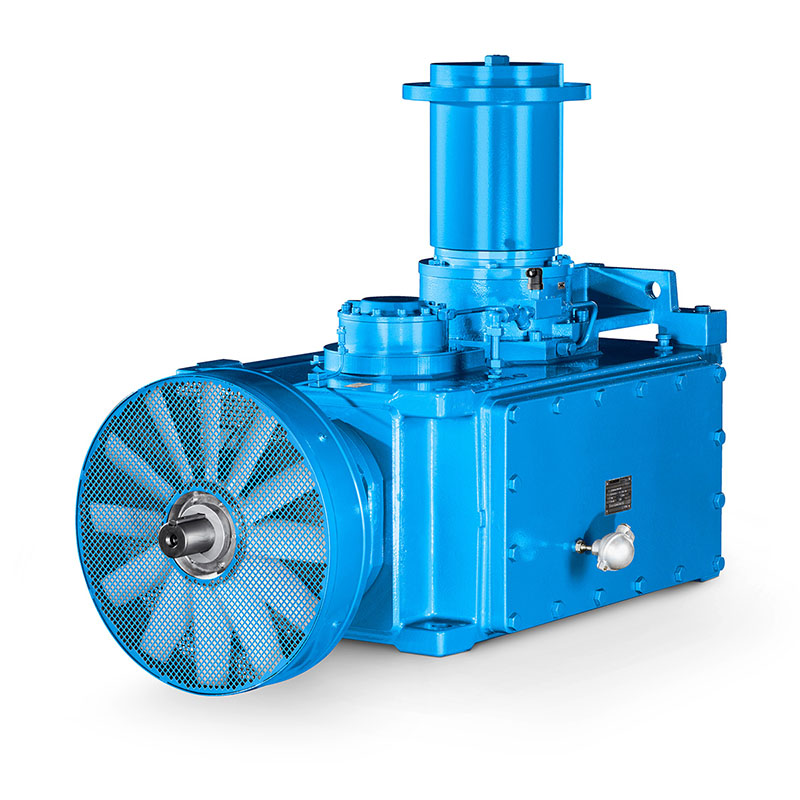

The required air stream for the cooling is produced by ventilators which are mounted on an output shaft of the gear unit. To enable the FLENDER Wet Cooling Tower Gear Units to absorb the enormous ventilation forces, the gear units are equipped with an additional axial bearing. Therefore, only application-adapted 2-staged bevel helical gear units are used to fulfill the special requirements of this application.

The motor is installed outside the cooling tower. He is mechanically connected to the gear unit that is placed right in the middle of the diffuser of the cooling tower via long Composite Couplings. These special couplings are also found in the FLENDER product range.

Your benefits at a glance

- Low noise emission due to torsionally rigid housings

- Variable dimensions of the output bearings for the different ventilator types (according to the ventilating rail)

- Highest operational reliability due to one-part housings, reinforced bearings, centrifugal discs on the ventilator shaft

- Additional cooling realized by fan cooler on the input shaft

- Long service life as a result of optimized gear unit selection and use of high-grade materials

- Complete drive system from a single source

Applications

Power generating industries, like:

- Biomass power plant

- Gas power plant

- Waste incineration plant

- Oil power plant