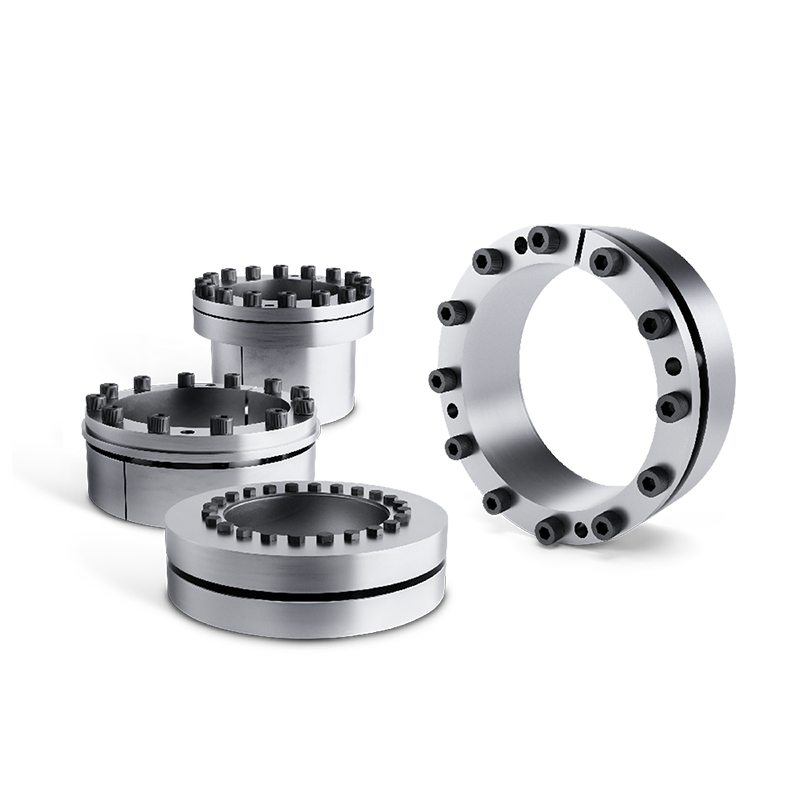

- Universally applicable, compact and backlash-free clamping elements for frictionally engaged connections

- Nominal torque range from TCl = 5 Nm up to 1,915,000 Nm (on request up to 7,394,000 Nm) with 12 types

- Temperature range from -20 °C to +160 °C

Fast, simple and secure connection

The FASTEX series offers heavy-duty, compact and backlash-free clamping elements for frictionally engaged connections. This provides another connection option for shafts and hubs in addition to the classic feather key connection. The effective connection solution further increases the combination variety and flexibility of the Flender coupling portfolio. The mode of operation of the clamping elements is based on pushing conical pressure rings onto a conical pressure sleeve using clamping screws. Due to their simple design, they allow extremely fast assembly and disassembly.

Portfolio for a wide range of applications

Various solutions are offered for a wide range of applications and industries. A distinction is made between internal and external clamping sets as well as self-centering and non-self-centering. Currently, ten different types of internal clamping sets and two types of external clamping sets are available. In the case of internal clamping sets, radial expansion at the contact surfaces generates radial forces inwards and outwards, thus ensuring frictional locking between the parts involved in the transmission of torque and forces. They are therefore in the flow of forces. The external clamping sets are not in direct force flow, instead they apply the forces to the shaft from the outside through the hub.

Your benefits at a glance

- Easy to align, fast assembly

- High power density

- Smooth use in Flender couplings

- Transmission of torques, axial and transverse forces, bending moments

- Detachable connection, reusable

- Perfectly suitable for reversing operation

Application examples

Chain drives, belt drives, elevators, cranes, sawmills, conveyor belts, mining, mills, mixers, floor conveyors, pumps, agricultural machinery, compressors, presses, crushers, shredders, packaging machines, cable winding machines, paternosters, industrial furnaces, extruders, paper machines, reactors, marine technology, textile plants, fans, printing plants, dryers, turbines...

Did you know?

Clamping elements enable a component-protecting application due to the low surface pressure. In addition, significant material costs can be saved due to the compact design.